VPSA Oxygen Equipment Used In Hospital, Reducing Maintenance And Operation Costs

| Product name |

VPSA Oxygen Generator

|

| Oxygen delivery |

≤600Nm3/hr

|

| Purity |

93±3%

|

| Pressure |

0.2-0.3 Mpa

|

| Atmospheric dew point |

≤-60℃

|

Working Principle Description:

The VPSA (Vacuum Pressure Swing Adsorption) oxygen generator follows a step-by-step process to generate oxygen:

Air Compression: Ambient air is drawn in and compressed using a compressor, increasing its pressure and concentration of oxygen.

Adsorption Towers: The compressed air is then directed into adsorption towers equipped with specialized adsorbents like molecular sieves or activated carbon.

Adsorption Phase: During this phase, the adsorbents selectively attract and capture nitrogen molecules from the compressed air, allowing oxygen to pass through and become enriched.

Pressure Drop Desorption: When the adsorption capacity of the adsorbents reaches its limit, the pressure in the towers is reduced. This causes the adsorbents to release the captured nitrogen molecules.

Oxygen Collection: The expelled nitrogen gas is expelled out of the system, while the oxygen-enriched gas is collected as the final product.

Tower Switching: To ensure continuous oxygen production, the system switches between different adsorption towers. This enables uninterrupted operation while allowing the saturated towers to regenerate.

By utilizing the principles of selective adsorption and pressure manipulation, the VPSA process effectively separates nitrogen from the air, resulting in the production of high-purity oxygen. This method offers flexibility, efficiency, and adaptability, making it well-suited for a wide range of industrial and medical applications.

Product Advantages:

● Low maintenance and operation costs: Compared to other oxygen supply methods, the maintenance and operation costs of VPSA oxygen equipment are usually lower. It does not require frequent replacement of gas cylinders or liquid oxygen supply, nor does it require special gas storage equipment. In addition, modern VPSA oxygen equipment typically have long lifespan and reliability, reducing the need for maintenance and component replacement.

●Sustainability and environmental protection: The VPSA oxygen generator does not involve the use of chemicals in the oxygen production process, and does not produce environmental pollutants such as wastewater and exhaust gas. It is a relatively environmentally friendly and sustainable oxygen supply method that meets the requirements of sustainable development.

●Reliable automatic control system: The VPSA oxygen generator is equipped with a reliable automatic control system that can monitor and adjust various parameters of oxygen production in real time. These parameters include pressure, temperature, flow rate, etc. to ensure the stable operation of the equipment and the quality of oxygen.

Technical parameters:

● Oxygen delivery: ≤600Nm3/hr;

● Purity: 93±3%

● Pressure: 0.2~0.3 Mpa

● Atmospheric dew point: ≤-60℃

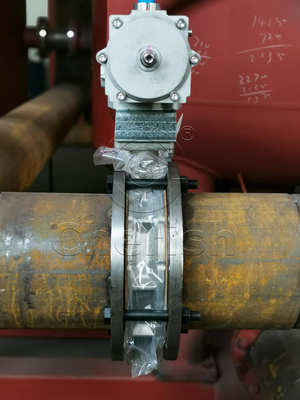

Product picture:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!